Product Description

Finite Element Analysis (FEA)data is available for this product at: 3m.com/FEA

3M™ VHB™ Tape LVO-110BF is a 0.045 inch (1.1 mm) thick black double-sided acrylic foam tape with PE film liner. The low odor adhesive on both sides bonds to a broad range of substrates and plastics, optimized for polypropylene and polystyrene. The very conformable foam provides good contact between substrates even when they are slightly mismatched. 3M™ VHB™ Tape LVO-110BF is part of the low VOC and low odor (LVO) tape family. Each product in this family has low odor adhesive and very conformable foam but varies in thickness.

Product Features

- 85% reduced VOC’s compared to common acrylic foam tape, tested to VDA278 standard

- Low in Odor – tested to VDA270 standard

- Fast and easy-to-use permanent bonding method provides high strength and long-term durability

- Virtually invisible fastening keeps surfaces smooth

- Can replace mechanical fasteners (rivets, welding, screws) or liquid adhesives

- Closed-cell foam creates a seal against water and moisture

- Pressure sensitive adhesive bonds on contact to provide immediate handling strength

- Allows the use of thinner, lighter weight and dissimilar materials

- This product might be suitable for use in indirect food contact applications. Please see the applicable Regulatory Data

Sheet for more information relating to FDA compliance.

Technical Information Note

The following technical information and data should be considered representative or typical only and should not be used for specification purposes.

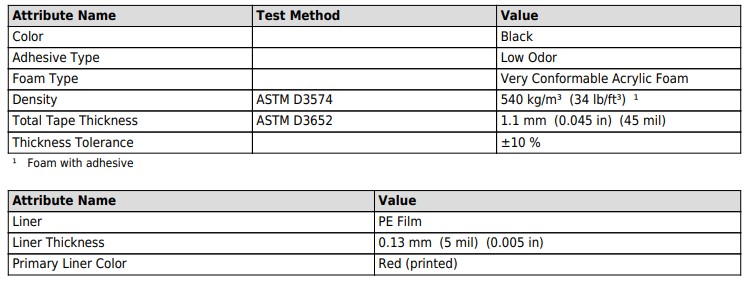

Typical Physical Properties

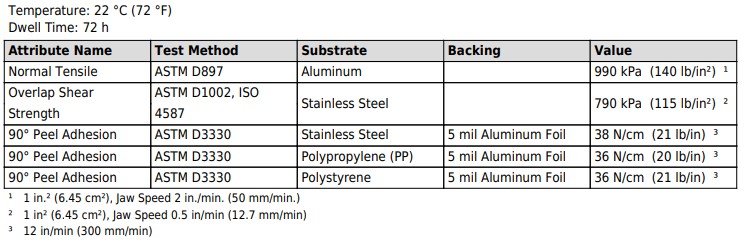

Typical Performance Characteristics

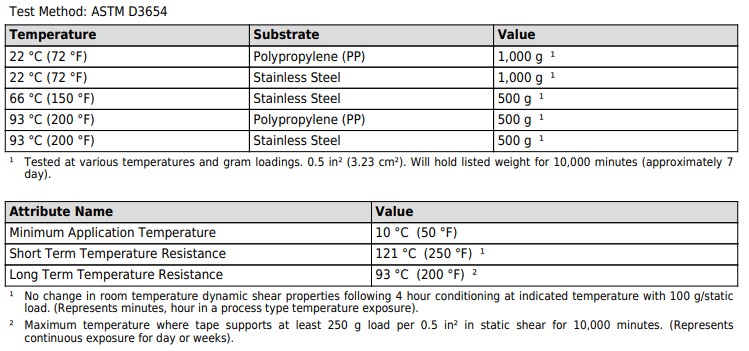

Static Shear

Converting

In addition to standard and custom roll sizes available from 3M through the distribution network, 3M™ VHB™ Tapes are also available in limitless shapes and sizes through the 3M Converter network. For additional information, contact 3M Converter Markets at 1-800-223-7427 or on the web at www.3M.com/converter.

Handling/Application Informatio

Surface Preparation

Clean: Most substrates should be cleaned with a 70/30 mixture of (IPA*)/Water prior to applying 3M™ VHB™ Tape.

Exceptions that may require additional surface preparation include:

• Heavy Oils: A degreaser or solvent-based cleaner may be required to remove heavy oil or grease from a surface and should be followed by cleaning with IPA/water.

• Abrasion: Abrading a surface, followed by cleaning with IPA/water, can remove heavy dirt or oxidation and can increase surface area to improve adhesion.

• Adhesion Promoters: Priming a surface can significantly improve initial and ultimate adhesion to many materials such as plastics and paints.

• Porous surfaces: Most porous and fibered materials such as wood, particleboard, concrete, etc. need to be sealed to provide a unified surface.

• Unique Materials: Special surface preparation may be needed for glass and glass-like materials, copper and copper containing metals, and plastics or rubber that contain components that migrate (e.g. plasticizers).

Refer to 3M Technical Bulletin “Surface Preparation for 3M™ VHB™ Tape Applications” for additional details and suggestions. (70-0704-8701-5)

*Note: Please consult with your local Air Quality District to ensure compliance. When using solvents, be sure to follow the manufacturer’s precautions and directions for use.

Application Techniques

Initial and Final Pressure Application:

ond strength is dependent upon the amount of adhesive-to-surface contact developed. Firm application pressure develops better adhesive contact and helps improve bond strength. Typically, good surface contact can be attained by applying enough pressure to ensure that the tape experiences approximately 100 kPa (15 psi) of pressure. Either roller or platen pressure can be used. When bonding two rigid parts, additional final pressure is often required to ensure that the bond line experiences 100 kPa (15 psi).

Tape Application Temperature:

The ideal tape application temperature range for 3M™ VHB™ Tapes is generally 21°C to 38°C (70°F to 100°F). Pressure sensitive adhesives use viscous flow to achieve substrate contact area. The minimum suggested application temperature for most 3M™ VHB™ Tapes is 10°C to 15°C (50°F to 60°F)

*Note: Initial tape application to surfaces at temperatures below these suggested minimums is not suggested because the adhesive becomes too firm to adhere readily. Ideally, all substrates and tape should be conditioned above the minimum application temperature in covered, weatherproof conditions until it is verified the substrates are at or above the minimum temperature. Once properly applied, low temperature holding is generally satisfactory.

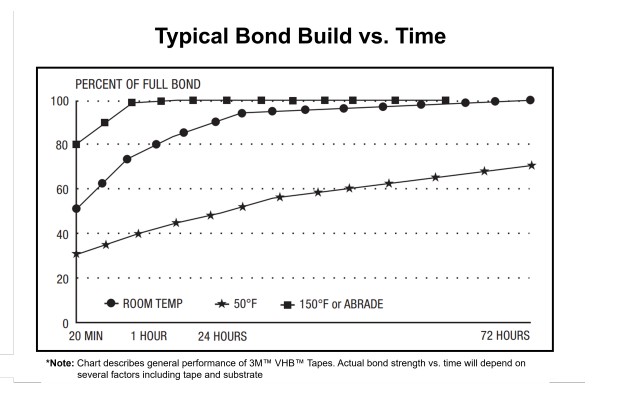

Bond Build Rate:

After application, the bond strength will gradually increase as the adhesive flows onto to the surface (also referred to as “wet out”). The bond build rate will depend on both tape and substrate, but generally, at room temperature, approximately 50% of ultimate bond strength will be achieved after 20 minutes, 90% after 24 hours, and 100% after 72 hours. Adhesive flow is faster at higher temperatures and slower at lower temperatures. Ultimate bond strength can be accelerated (and in some cases bond strength can be increased) by exposure to elevated temperature (e.g. 66°C [150°F] for 1 hour). This can provide better adhesive wet out onto the substrates. Abrasion (~180 grit), or the use of primers/adhesion promoters can also increase both bond strength as well as the bond build rate.

Design Considerations

Adhesion:

Adhesion to the substrate is critical to achieving high bond strength. Adhesives must flow onto the substrate surfaces in order to achieve intimate contact area and allow the molecular force of attraction to develop. The degree of flow of the adhesive on the substrate is largely determined by the surface energy of the substrate.

Tape Usage:

Use the right amount of VHB™ Tape to handle the expected stresses. Because 3M™ VHB™ Tapes are viscoelastic by nature, their strength and stiffness is a function of the rate at which they are stressed. They behave stronger when experiencing a higher rate of stress load (dynamic stresses) and will tend to show creep behavior with stress loads that act over a long period of time (static stresses). As a general rule, for static loads, approximately four square inches of tape should be used for each pound (57 cm² of tape per kg) of weight to be supported in order to prevent excessive creep. For dynamic loads a useful design factor is 12 lb/in2 (85 kPa) for most dynamic stresses in general applications.

Tape Thickness:

Achieving good contact is also important. The necessary thickness of tape depends on the rigidity of substrates as well as their flatness and/or irregularity. While 3M™ VHB™ Tape will conform to a certain amount of irregularity, they will not flow to fill large gaps between the materials. When bonding rigid materials with normal flatness, consider use of tapes with thickness of 45 mils (1.1 mm) or greater. As substrate flexibility increases, thinner tapes may be considered.

Thermal Expansion/Contraction:

3M™ VHB™ Tapes perform well in applications where two bonded surfaces may expand and contract at different rates. Assuming good adhesion to both substrates, VHB™ Tape can typically tolerate differential movement in the shear plane up to 3 times (300%) of their thickness.

Bond Flexibility:

While an advantage for many applications where allowing differential movement is a benefit, the tape bonds are typically more flexible than alternative fastening methods. Suitable design modifications or periodic use of rigid fasteners/adhesives may be necessary if additional stiffness is required.

Industry Specifications

FDA Statement

This product might be suitable for use in food contact applications. Please see the applicable Regulatory Data Sheet for more information relating to FDA compliance.

Storage and Shelf Life

This product has a shelf life of 24 months from date of manufacture when stored at 4°C to 38°C (40°F to 100°F) and 0-95% relative humidity. The optimum storage conditions are 22°C (72°F) and 50% relative humidity. Performance of tapes is not projected to change even after shelf life expires; however, 3M does suggest that 3M™ VHB™ Tapes are used prior to the shelf life date whenever possible. The manufacturing date is available on all 3M™ VHB™ Tapes as the lot number, typically marked on the core or on a label on the outer roll lap. The lot number, typically a 4 digit code, is a Julian date (Y D D D). The first digit refers to the year of manufacture, the last 3 digits refer to the days after January 1. Example: A lot number of 7266 (or 17266) would translate to a date of manufacture of Sept. 23 (266th day of year) in 2017.

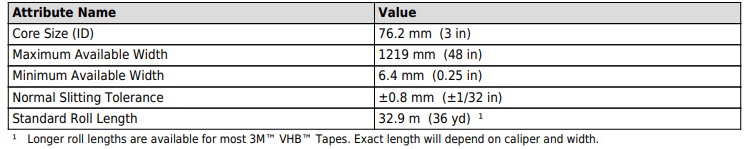

Available Sizes

Automotive Disclaimer

elect Automotive Applications: This product is an industrial product and has not been designed or tested for use in certain automotive applications, such as automotive electric powertrain battery or high voltage applications, which may require the product to be manufactured in a IATF certified facility, meet a Ppk of 1.33 for all properties, undergo an automotive production part approval process (PPAP), or fully adhere to automotive design or quality system requirements (e.g., IATF 16949 or VDA 6.3). Customer assumes all responsibility and risk if customer chooses to use this product in these applications.

Information

Technical Information: The technical information, guidance, and other statements contained in this document or otherwise provided by 3M are based upon records, tests, or experience that 3M believes to be reliable, but the accuracy, completeness, and representative nature of such information is not guaranteed. Such information is intended for people with knowledge and technical skills sufficient to assess and apply their own informed judgment to the information. No license under any 3M or third party intellectual property rights is granted or implied with this information.

Product Selection and Use: Many factors beyond 3M’s control and uniquely within user’s knowledge and control can affect the use and performance of a 3M product in a particular application. As a result, customer is solely responsible for evaluating the product and determining whether it is appropriate and suitable for customer’s application, including conducting a workplace hazard assessment and reviewing all applicable regulations and standards (e.g., OSHA, ANSI, etc.). Failure to properly evaluate, select, and use a 3M product and appropriate safety products, or to meet all applicable safety regulations, may result in injury, sickness, death, and/or harm to property.

Warranty, Limited Remedy, and Disclaimer: 3M warrants for 24 months from the date of 3M manufacture that 3M™ VHB™ Tape will be free of defects in material and manufacture. 3M MAKES NO OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR ARISING OUT OF A COURSE OF DEALING, CUSTOM, OR USAGE OF TRADE. This warranty does not cover damage resulting from the use or inability to use 3M™ VHB™ Tape due to misuse, workmanship in application, or application or storage not in accordance with 3M recommended procedures (except to the extent 3M approves and issues a specific application warranty, for which the customer must apply, receive 3M approval, and meet all applicable warranty and process requirements, the additional details, terms, and conditions of which are available from 3M). If a 3M product does not conform to this warranty, then the sole and exclusive remedy is, at 3M’s option, replacement of the 3M product or refund of the purchase price.

Limitation of Liability: Except for the limited remedy stated above, and except to the extent prohibited by law, 3M will not be liable for any loss or damage arising from or related to the 3M product, whether direct, indirect, special, incidental, or consequential (including, but not limited to, lost profits or business opportunity), regardless of the legal or equitable theory asserted, including, but not limited to, warranty, contract, negligence, or strict liability. Disclaimer: 3M industrial and occupational products are intended, labeled, and packaged for sale to trained industrial and occupational customers for workplace use. Unless specifically stated otherwise on the applicable product packaging or literature, these products are not intended, labeled, or packaged for sale to or use by consumers (e.g., for home, personal, primary or secondary school, recreational/sporting, or other uses not described in the applicable product packaging or literature), and must be selected and used in compliance with applicable health and safety regulations and standards (e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and limitations, and the user must take any action required under any recall, field action or other product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness, or death. For help with product selection and use, consult your on-site safety professional, industrial hygienist, or other subject matter expert. For additional product information, visit www.3M.com.

ISO Statement

This product was manufactured under a 3M quality system registered to ISO 9001 standards.