Product Description

3M™ UHMW Polyethylene Tapes are film coated with a rubber adhesive which provides an excellent abrasion resistant surface. These tapes feature a unique combination of properties that make it ideal for many tough impact wear or sliding applications. 3M™ UHMW-PE Film Tape 5421 is a thinner version of 3M™ UHMW- PE Film Tape 5423.

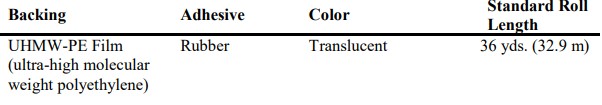

Product Construction

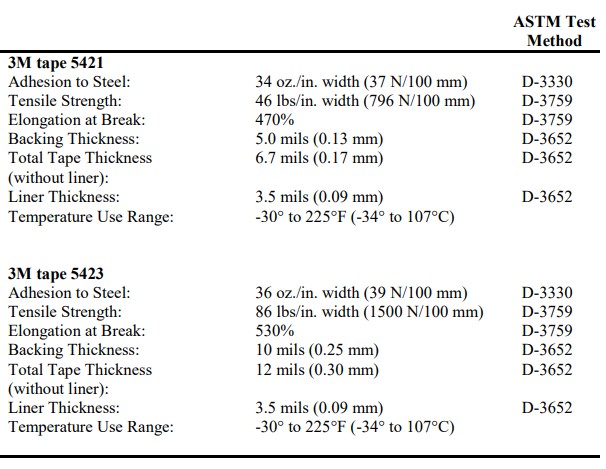

Typical Physical Properties

Note: The following technical information and data should be considered representative or typical only, and should not be used for specification purposes.

Features

- Tape demonstrated no evidence of wear through after Taber Abrasion at 1000 cycles, using CS-10 wheel and 1000g load when applied to S-37 mounting sheet.

- Low water vapor transmission rate < 0.50 g/100in.2/24hrs.

- Thick caliper UHMW polyethylene tape for extended service life as a protective surface against tough impact wear or sliding applications.

- Outstanding abrasion resistance so will outwear PTFE and other materials in sliding applications.

- Low coefficient of friction characteristics is exceeded only by PTFE.

- UHMW-PE tape can be used where lubrication is not possible because of contamination.

- Rubber Adhesive provides good initial tack for immediate bonding to material surface.

- Liner makes it ideal for fabricating or die-cutting into various lengths and shapes.

Application Ideas

- Noise reduction between dissimilar parts.

- Reduce squeaks, rattles and other noises that occur with movement

- Lining of conveyer guide rails, tank and bin liners, and discharge chutes.

- Protection for aluminum sheets on stretch forming presses.

- Liners for Spray booths.

- Slick surface for easy glide for drawers and cabinets.

Storage

Store under normal conditions of 60° to 80°F (16° to 27°C) and 40 to 60% relative humidity in the original packaging material.

Shelf Life

To obtain best performance, use this product within 18 months from date of manufacture.

Technical Information

The technical information, recommendations and other statements contained in this document are based upon tests or experience that 3M believes are reliable, but the accuracy or completeness of such information is not guaranteed.

Product Use

Many factors beyond 3M’s control and uniquely within user’s knowledge and control can affect the use and performance of a 3M product in a particular application. Given the variety of factors that can affect the use and performance of a 3M product, user is solely responsible for evaluating the 3M product and determining whether it is fit for a particular purpose and suitable for user’s method or application.

Warranty, Limited Remedy, and Disclaimer

Unless an additional warranty is specifically stated on the applicable 3M product packaging or product literature, 3M warrants that each 3M product meets the applicable 3M product specification at the time 3M ships the product. 3M MAKES NO OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOS OR ANY IMPLIED WARRANTY OR CONDITION ARISING OUT OF A COURSE OF DEALING, CUSTOM OR USAGE OF TRADE. If the 3M product does not conform to this warranty, then the sole and exclusive remedy is, at 3M’s option, replacement of the 3M product or refund of the purchase price.

Limitation of Liability

Except where prohibited by law, 3M will not be liable for any loss or damage arising from the 3M product, whether direct, indirect, special, incidental or consequential, regardless of the legal theory asserted, including warranty, contract, negligence or strict liability.