Product Description

3M™ Industrial Protective Films 7070UV and 7071UV are abrasion resistant, pressure sensitive adhesive backed film products designed to protect multiple industrial surfaces from damage caused by abrasion, scratching, erosion, UV and minor impacts. These rugged clear films are durable, flexible, and able to conform to curved surfaces while being easy to apply.

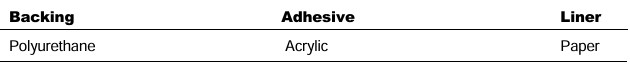

Product Construction

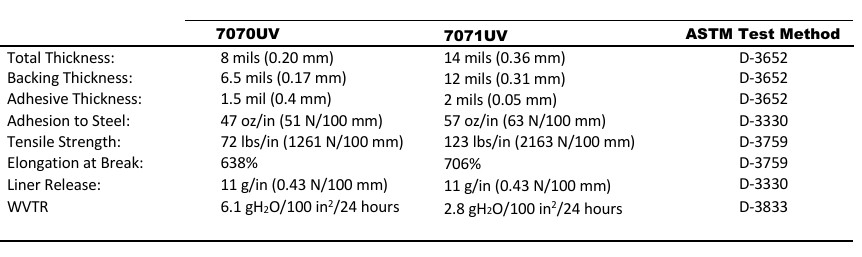

Typical Physical Properties

Note: The following technical information and data should be considered representative or typical only and should not be used for specification purposes.

Features

- Polyurethane backing resists punctures and tearing. 7071UV is suggested for more extreme applications.

- Provided on a paper liner for ease of die cutting specific shapes.

- Easily applied with simple tools in a minimal amount of time.

- Clear color will not obscure surfaces.

- Product may be used to protect surfaces outdoors with 7070UV effective for 1 year and 7071UV effective for 2 years. Conclusions based on simulated extreme environmental exposure and individual applications will vary.

- Maximum service temperature 200°F (93.3°C)

- Both films demonstrated no wear through with minimal visible scuff pattern after Taber abrasion testing conducted using modified ASTM D-4060 1000g weight, 1000 cycles with S-37 mounting sheet.

Application Techniques

- For best results, surfaces must be clean and free of dirt, debris and oils and films should be applied when surface temperature is between 50°F (10°C) and 80°F (27°C).

- Use of an application solution is suggested for easy positioning and squeegee application.

- For detailed application instructions and tips, see 3M Technical Bulletin on installation of Industrial Protective Films.

3Storage

Keep film in a clean area, away from excessive moisture and out of direct sunlight. Store rolls under normal conditions of 60° to 80°F (16° to 27°C) and 40 to 60% R.H. in the original carton.

Shelf Life<

To obtain best performance, use this product within 12 months from date of manufacture.

Technical Information

The technical information, recommendations and other statements contained in this document are based upon tests or experience that 3M believes are reliable, but the accuracy or completeness of such information is not guaranteed.

Product Use

Many factors beyond 3M’s control and uniquely within user’s knowledge and control can affect the use and performance of a 3M product in a particular application. Given the variety of factors that can affect the use and performance of a 3M product, user is solely responsible for evaluating the 3M product and determining whether it is fit for a particular purpose and suitable for user’s method of application.

Warranty, Limited Remedy, and Disclaimer

Unless an additional warranty is specifically stated on the applicable 3M product packaging or product literature, 3M warrants that each 3M product meets the applicable 3M product specification at the time 3M ships the product. 3M MAKES NO OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY IMPLIED WARRANTY OR CONDITION ARISING OUT OF A COURSE OF DEALING, CUSTOM OR USAGE OF TRADE. If the 3M product does not conform to this warranty, then the sole and exclusive remedy is, at 3M’s option, replacement of the 3M product or refund of the purchase price

Limitation of Liability

Except where prohibited by law, 3M will not be liable for any loss or damage arising from the 3M product, whether direct, indirect, special, incidental or consequential, regardless of the legal theory asserted, including warranty, contract, negligence or strict liability.