Product Features

- Dries quickly to a firm bond.

- Excellent resistance to water, plasticizer migration, many detergent and soap solutions, oils and grease.

- A general purpose adhesive for bonding most vinyls, ceramics, glass, leather and cloth to a variety of substrates.

Technical Information Note

The following technical information and data should be considered representative or typical only and should not be used for specification purposes.

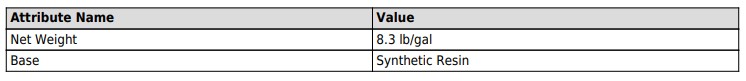

Typical Uncured Physical Properties

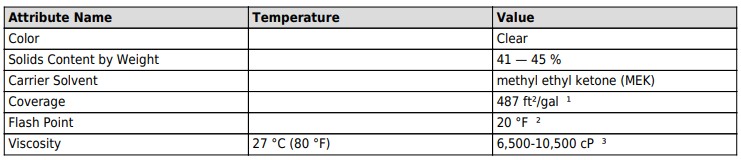

Typical Physical Properties

mil dry film

Closed Cup

Brookfield Viscometer RVF #5 sp. @ 20 rpm

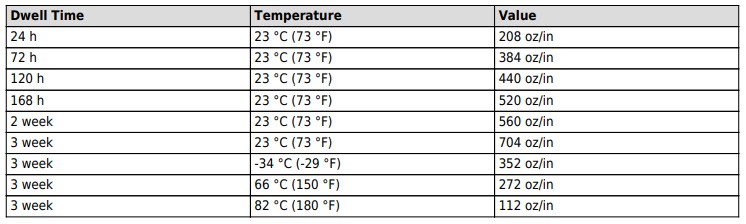

Typical Performance Characteristics

180° Peel Adhesion

Substrate: Canvas to Steel

Handling/Application Information

Directions for Use

1. Surface Preparation: Best results are achieved on clean, dry surfaces. Oil, grease and other contaminants can be removed by wiping with a solvent such as methyl ethyl ketone (MEK).*

2. Application: Apply adhesive to one or both surfaces (best results are obtained by coating both surfaces) and bond immediately using firm pressure.

3. Drying Time: Allow to dry a minimum of 24 hours for maximum strength.

4. Cleanup: Remove unhardened or hardened material with cloth dampened with a solvent such as methyl ethyl ketone (MEK).*

*Note: When using solvents, extinguish all ignition sources and follow the manufacturer’s precautions and directions for use.

Application Equipment

Note:Appropriate application equipment can enhance adhesive performance. The user is responsible for evaluating application equipment in light of the user’s particular purpose and method of application.

1. Pumping

5-Gallon Pail Dispensing System

Pump – 9:1 ratio double acting ball check type pump, 11.0 cubic inches per cycle, 41/4" diameter air motor minimum. Pail cover to be used to reduce solvent loss.

55-Gallon Drum Dispensing System

Pump – 10:1 ratio double acting ball check type pump, 11.0 cubic inches per cycle, 41/4" diameter air motor minimum, Bung mount type.

2. Accessories

Hose – 1000 psi minimum working pressure, nylon lined. Flow rate at 40°F, 20 ft. of 3/4-ID plus 10 ft. 1/2-ID and a flow gun equals 1 pound/minute at pump air pressure of 75 psi.

3. Chemical Resistance Requirements

Synthetic materials in contact with this product must be resistant to ketones and aromatic solvents. Compare, nylon or PTFE coatings are suggested for packings and gaskets.

Storage and Shelf Life

Store under normal conditions of 16° to 27°C (60° to 80°F) and 40 to 60% relative humidity in the original, unopened packaging, out of direct sunlight. Lower temperatures cause increased viscosity of a temporary nature. For best performance, use this product within 30 months from date of manufacture.

Precautionary Information

Refer to Product Label and Material Safety Data Sheet for health and safety information before using this product. For additional health and safety information, call 1-800-364-3577

Automotive Disclaimer

elect Automotive Applications:

This product is an industrial product and has not been designed or tested for use in certain automotive applications, such as automotive electric powertrain battery or high voltage applications, which may require the product to be manufactured in a IATF certified facility, meet a Ppk of 1.33 for all properties, undergo an automotive production part approval process (PPAP), or fully adhere to automotive design or quality system requirements (e.g., IATF 16949 or VDA 6.3). Customer assumes all responsibility and risk if customer chooses to use this product in these applications.

Information

Technical Information: The technical information, guidance, and other statements contained in this document or otherwise provided by 3M are based upon records, tests, or experience that 3M believes to be reliable, but the accuracy, completeness, and representative nature of such information is not guaranteed. Such information is intended for people with knowledge and technical skills sufficient to assess and apply their own informed judgment to the information. No license under any 3M or third party intellectual property rights is granted or implied with this information.

Product Selection and Use: Many factors beyond 3M’s control and uniquely within user’s knowledge and control can affect the use and performance of a 3M product in a particular application. As a result, customer is solely responsible for evaluating the product and determining whether it is appropriate and suitable for customer’s application, including conducting a workplace hazard assessment and reviewing all applicable regulations and standards (e.g., OSHA, ANSI, etc.). Failure to properly evaluate, select, and use a 3M product and appropriate safety products, or to meet all applicable safety regulations, may result in injury, sickness, death, and/or harm to property.

Warranty, Limited Remedy, and Disclaimer: Unless a different warranty is specifically stated on the applicable 3M product packaging or product literature (in which case such warranty governs), 3M warrants that each 3M product meets the applicable 3M product specification at the time 3M ships the product. 3M MAKES NO OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR ARISING OUT OF A COURSE OF DEALING, CUSTOM, OR USAGE OF TRADE. If a 3M product does not conform to this warranty, then the sole and exclusive remedy is, at 3M’s option, replacement of the 3M product or refund of the purchase price. Limitation of Liability: Except for the limited remedy stated above, and except to the extent prohibited by law, 3M will not be liable for any loss or damage arising from or related to the 3M product, whether direct, indirect, special, incidental, or consequential (including, but not limited to, lost profits or business opportunity), regardless of the legal or equitable theory asserted, including, but not limited to, warranty, contract, negligence, or strict liability.

Disclaimer: 3M industrial and occupational products are intended, labeled, and packaged for sale to trained industrial and occupational customers for workplace use. Unless specifically stated otherwise on the applicable product packaging or literature, these products are not intended, labeled, or packaged for sale to or use by consumers (e.g., for home, personal, primary or secondary school, recreational/sporting, or other uses not described in the applicable product packaging or literature), and must be selected and used in compliance with applicable health and safety regulations and standards (e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and limitations, and the user must take any action required under any recall, field action or other product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness, or death. For help with product selection and use, consult your on-site safety professional, industrial hygienist, or other subject matter expert. For additional product information, visit www.3M.com.

ISO Statement

This product was manufactured under a 3M quality system registered to ISO 9001 standards.