Product Description

3M™ Fast Tack Water Based Adhesive 1000NF is a high performance water-based, one part adhesive formulated for fast bonding and long term heat resistant bonds. Adheres to many types of flexible foam, latex foams, fabric, polyester fiberfill, wood, plywood, particleboard and many plastic and metal surfaces.

Key Features

- Fast bonding. Depending on substrates, handling strength bonds can be made without complete drying.

- Repositionable while adhesive is wet and aggressively tacky.

- Long term stable bonds. Good heat resistance.

- Bonds most foamed plastics, plastic laminates, wood, plywood and canvas to themselves and to each other. Performs best when at least one substrate is porous.

- Non-flammable in the wet state.

- Acrylic based. Contains no polychloroprene. Contains no natural rubber latex.

Certified to GREENGUARD® Product Emission Standard For Children and Schools(SM) for low emitting interior building materials:

Addresses or Contributes to LEED® EQ Credit 4.1: Low Emitting Materials: Adhesive and Sealants

Addresses or Contributes to LEED® EQ Credit 4.5: Low Emitting Materials: Furniture and Furnishings

Addresses or Contributes to LEED® EQ Credit 4.5: Low Emitting Materials: Furniture and Furnishings

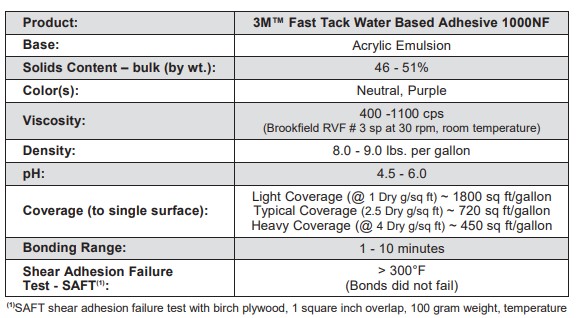

Typical Physical Properties

Note: The following technical information and data should be considered representative or typical only and should not be used for specification purposes.

Special Note

3M™ Fast Tack Water Based Adhesive 1000NF is intended for use in a wide variety of applications. Coverage and application procedure will vary for each use. User should test for suitability with their process and performance requirements.

In general, key considerations when using 3M™ Fast Tack Water Based Adhesive 1000NF are:

- Ensure adequate adhesive is applied over the entire area to be bonded. This may mean an additional coating is required.

- Bonds should be made when the adhesive feels aggressively tacky.

- Apply sufficient pressure to ensure good contact between the surfaces.

See Application Tips & Tricks Pamphlet for more information.

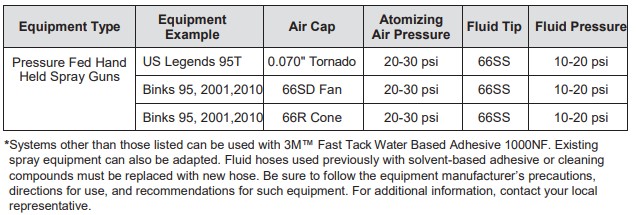

Application Equipment Suggestions

Appropriate application equipment can enhance adhesive performance. We suggest the following application equipment for the user’s evaluation in light of the user’s particular purpose and method of application.

Air Atomizing Spray Equipment

Pressure Pots

Stainless steel pressure pots recommended. Non-stainless may be used with plastic liners if dip tube and fittings are changed to plastic or stainless steel.

Pumping Equipment

1.5 inch inner diameter (minimum) plastic diaphragm pump with PTFE checks and diaphragms. All pumps should be short stroked for pump longevity. For additional information, contact your local representative.

Filter (output)

Typically, 30# mesh is suitable: for example, Graco® model 12 (stainless steel) with filter bag #521-264 or equivalent.

Hoses

All fluid hoses should be nylon or polyester lined. Hose fittings should be stainless steel or plastic. The typical fluid hose length @ 1/4 inch i.d. should be 15 to 25 ft. Use of larger fluid hose i.d. or lengths less than 15 ft. will result in loss of fluid pressure control. Use of smaller fluid hose i.d. or lengths greater than 25 ft. can result in product coagulation in the line.

Note: New fluid lines are recommended due to potential incompatibility with other adhesives. Use only plastic and stainless steel fittings in contact with adhesive. Adhesive is incompatible with steel, galvanized steel, and cast aluminum parts.

Handling/Application Information

Directions for Use:

Bonds can be made by applying 3M™ Fast Tack Water Based Adhesive 1000NF to one or both of the surfaces to be bonded. For maximum strength, apply to both substrates. For lighter duty uses, application to only one surface may be acceptable. Single surface application may require heavier coverage and longer dry time. User should evaluate the adhesive to determine which method(s) is suitable for their use. Bonds to porous substrates can generally be made without significant drying, typically < 30 seconds depending on environmental factors and adhesive coverage. Non-porous substrates need to dry until tacky to touch.

All applications benefit from attention to:

1.Surface Preparation: Use only on clean, dry surfaces. Contamination of surfaces with oil, grease or release agents will prevent good, strong bonds.

2.Application: Adhesive does not require agitation before use. Adhesive can be brushed, rolled or spray applied. The quickest bonds can be made through spray application. Adjust the spray equipment to give a fine, mist-like spray pattern. Spray a uniform, light coat of adhesive to one or both surfaces holding spray applicator 10-15 inches from surface.

3.Coverage: Coverage will depend on the surface porosity of substrates, and strength of adhesive bond required. In all cases, user evaluation will be required to determine the optimum coverage levels.

Note: Application of adhesive at high coating weights or using a coarse spray pattern may result in longer activation times.

4.Activation Time: The adhesive may activate sufficiently to permit making bonds within 30 seconds after application when bonding porous substrates. Bonds such as foam or fabric to smooth, nonporous surfaces such as plastic or metal will require longer activation times. In general, bonds should be made when the adhesive coating feels aggressively tacky. This time is dependent on the amount of adhesive applied. Bonds may be made up to 1 - 10 minutes after application depending on ambient temperature and humidity conditions. See Note above.

5.Assembly and Bonding: Pressure sufficient to assure the substrates make contact should be applied to the bond line by manual or mechanical methods.

6.Cleanup: Wet adhesive may be removed with water containing a small amount of vinegar.* Follow with a flush of clean water. Dry adhesive may be removed with a combination of 3M™ Adhesive Remover Low VOC < 20% or 3M™ Citrus Base Cleaner** or equivalent and mechanical systems such as wire brushing. Dry adhesive cannot be removed from porous surfaces such as foams or fabrics.

*Cleaning Solution: One part vinegar to five parts water.

**Note: When using solvents, extinguish all ignition sources, including pilot lights, and follow the manufacturer’s precautions and directions for use.

Storage

Best storage temperature is 60-80°F (15-27°C). Higher temperatures reduce normal storage life. Lower temperatures cause increased viscosity of a temporary nature. This water-dispersed adhesive will become unusable with prolonged storage below 40°F (4°C). Rotate stock on a “first in, first out” basis. Protect from freezing.

Shelf Life

When stored at the recommended temperature in the original, unopened container, this product has a shelf life of 18 months from date of manufacture.

Precautionary Information

Refer to Product Label and Material Safety Data Sheet for health and safety information before using this product. For additional health and safety information, call 1-800-364-3577 or (651) 737-6501.

Technical Information

The technical information, recommendations and other statements contained in this document are based upon tests or experience that 3M believes are reliable, but the accuracy or completeness of such information is not guaranteed.

Product Use

Many factors beyond 3M’s control and uniquely within user’s knowledge and control can affect the use and performance of a 3M product in a particular application. Given the variety of factors that can affect the use and performance of a 3M product, user is solely responsible for evaluating the 3M product and determining whether it is fit for a particular purpose and suitable for user’s method of application.

Warranty, Limited Remedy, and Disclaimer

Unless an additional warranty is specifically stated on the applicable 3M product packaging or product literature, 3M warrants that each 3M product meets the applicable 3M product specification at the time 3M ships the product. 3M MAKES NO OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY IMPLIED WARRANTY OR CONDITION ARISING OUT OF A COURSE OF DEALING, CUSTOM OR USAGE OF TRADE. If the 3M product does not conform to this warranty, then the sole and exclusive remedy is, at 3M’s option, replacement of the 3M product or refund of the purchase price.

Limitation of Liability

Except where prohibited by law, 3M will not be liable for any loss or damage arising from the 3M product, whether direct, indirect, special, incidental or consequential, regardless of the legal theory asserted, including warranty, contract, negligence or strict liability.